Motor Windings: What are the differences?

Motor windings can take many shapes or forms. However 3-phase distributed windings are the most commonly used in AC motors for industrial applications, which will be the focus of this article. The discussion which follows is equally applicable to the use of this type of winding in induction motors or in permanent magnet synchronous motors.

The objective of the distributed winding is to produce a sinusoidal Magneto-Motive Force (MMF) distribution in the motor air gap. This MMF is produced when a balanced set of 3 phase AC currents flow in the phase windings. It is the MMF, combined with the motor magnetic circuit design, which gives rise to a travelling wave of flux in the air gap to produce the required motor torque.

Windings are made up of several coils wound from insulated copper or in some cases aluminium wire. Several strands of wire can be connected in parallel to form a single conductor which is then wound into a coil which will have several turns. The number of turns will depend on specific design requirements.

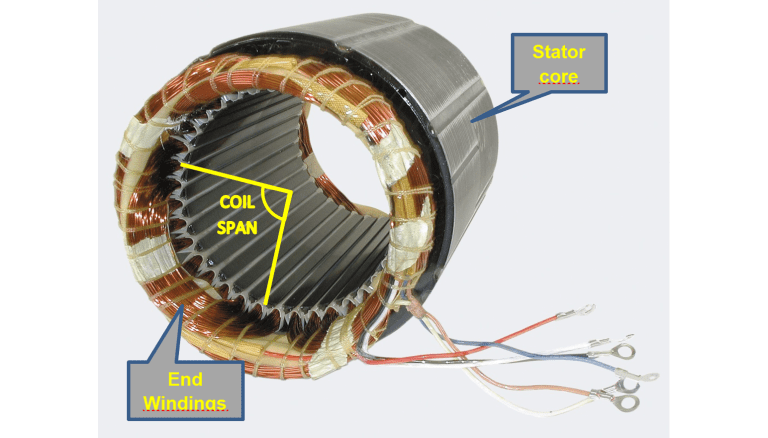

A distributed winding consists of several coils inserted into the slots of the motor stator as shown below. The number of coils will depend on the number of stator slots, the number of phases (in our case 3) and the number of motor poles, p.

Each coil will span several slots. A full-pitch winding will have coils whose average span corresponds to a number of slots equal to the pole-pitch or 360°/p whereas a short-pitch winding will span fewer slots. The Figure below shows a full-pitch winding for a typical 4 pole motor.

A part of the winding will be in the slot where it contributes to motor torque production. The remainder will be in the end windings which do not contribute to motor torque production. Careful design is therefore needed to avoid an unnecessary waste of expensive copper. Furthermore, good thermal performance drives the need for high slot fill and end winding thermal management. These factors are often limited by manufacturing process considerations.An ideal distributed winding will have an infinite number of coils placed in an infinite number of slots such that the MMF space distribution is a perfect sinusoid. This is clearly not possible in practice so a best compromise needs to be found to meet the required performance.

Coils of different phases need to be insulated from each other and from the stator core in order to avoid short circuits and failure. Insulation constitutes additional thermal barriers which will limit the ability to transfer heat from the inside of the machine to the outside. Air voids will be present between winding wires and between the insulation, winding and stator core. These voids are filled with a resin using an impregnation process which improves heat transfer and further improves winding insulation.

Electric motor applications are many and varied. Different applications impose different requirements on the motor design. Several of these requirements will be impacted by the winding design and can include:

- Minimisation of harmonic losses for improved efficiency

- Reduce torque pulsations

- Reduce acoustic noise and vibrations

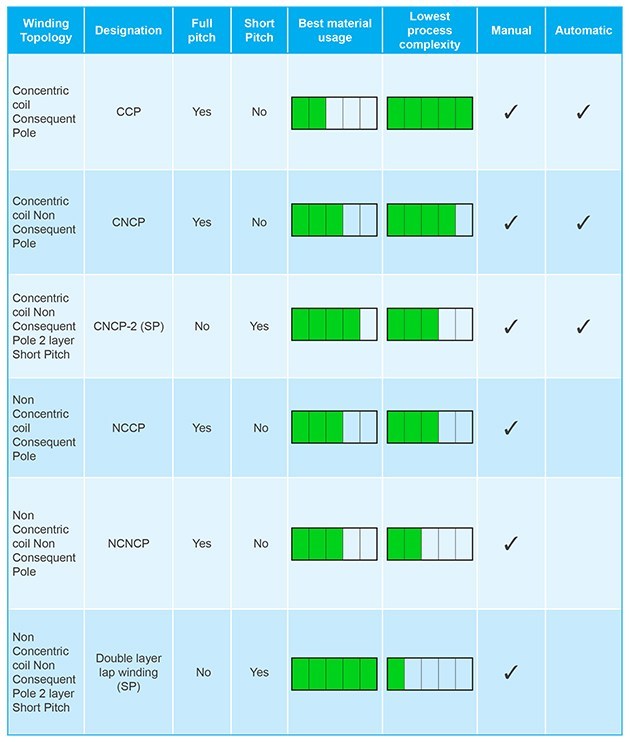

Several winding layouts are possible to achieve the same electrical performance. The choice of these layouts will be determined by manufacturing constraints which are strongly influenced by the level of automation used to produce the winding.

The table below gives some of the most common winding configurations along with the main selection criteria.

It is clear that strong compromises need to be made between technical requirement, process complexity, the level of automation and cost. This means that motor designers need to work closely with manufacturing engineering to define the best overall solution.

If you need any support on your motor, email us at motors@quantum-controls.co.uk.